By Jocelyn Hare McLaughlin

Water damage can be a nightmare for homeowners and business owners alike, and one of the most challenging aspects of water restoration is drying out wall cavities. When water seeps into walls, it can cause mold growth, structural damage, and unpleasant odors. That’s why it’s crucial to ensure that wall cavities are dried thoroughly and efficiently. In this blog post, we’ll discuss wall cavity drying and provide water restoration professionals with some essential tips for achieving successful drying outcomes.

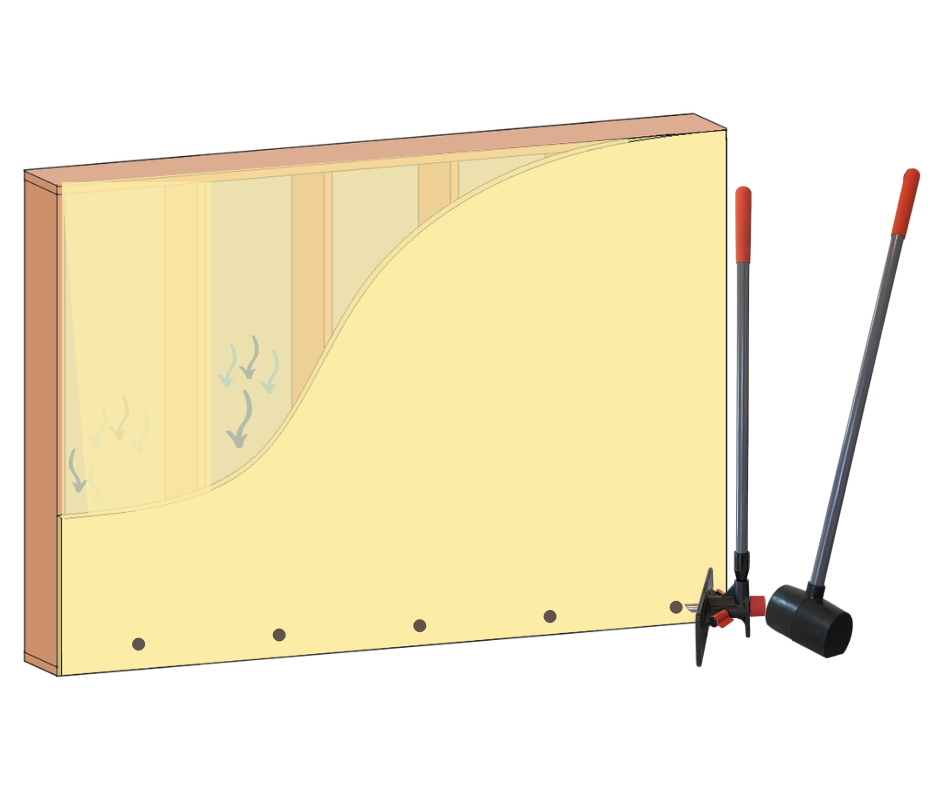

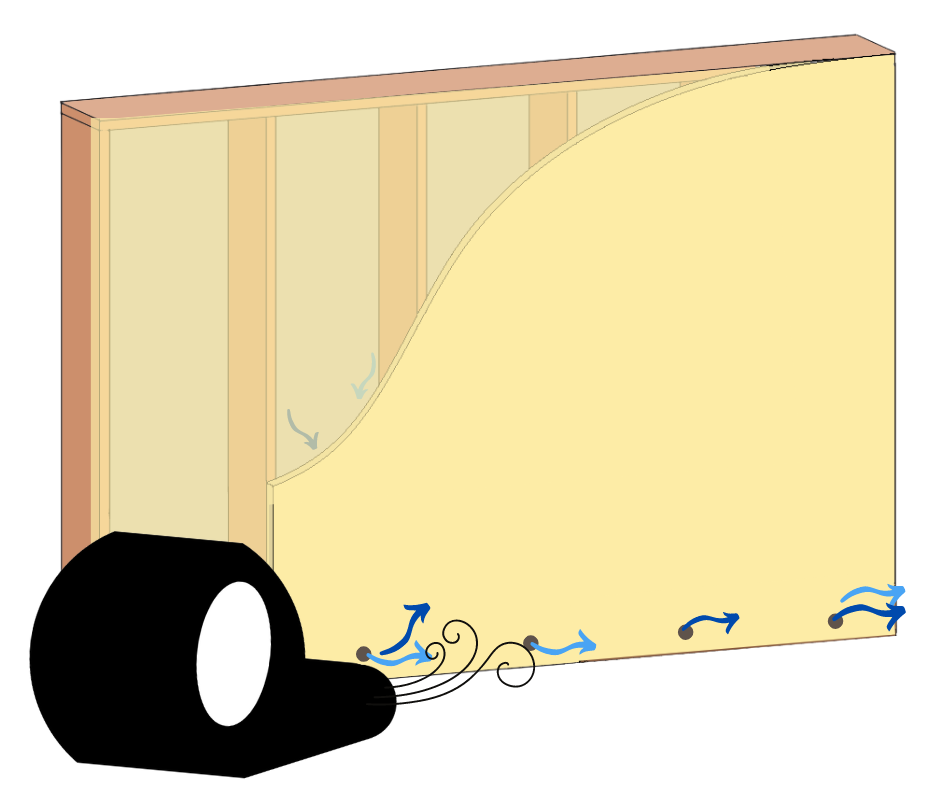

A wall cavity is a space between the exterior and interior walls of a building. This space usually contains insulation, electrical wiring, plumbing, and other elements that can be damaged by water intrusion. When water enters the wall cavity, it can take a long time to evaporate due to the lack of airflow and sunlight, making it challenging to dry out effectively.

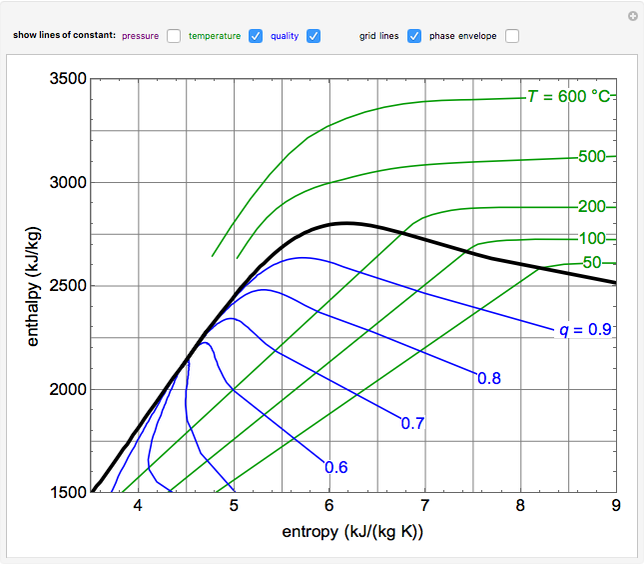

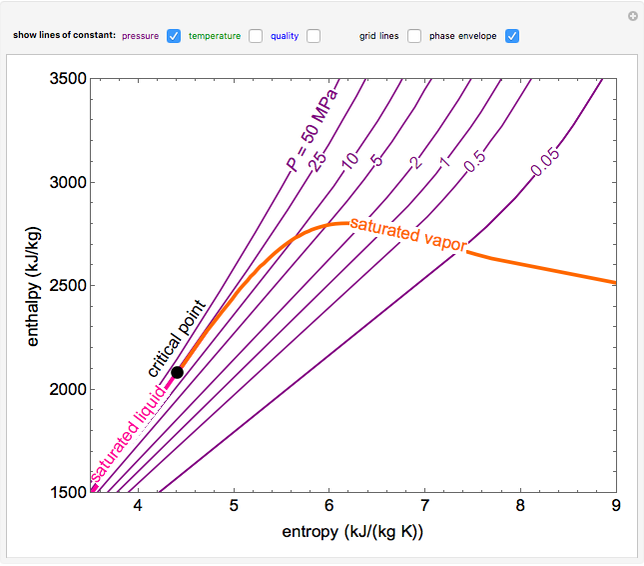

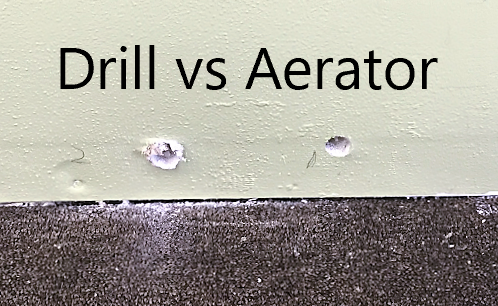

One of the most effective methods for drying wall cavities is using specialized drying equipment. This equipment includes dehumidifiers, air movers, moisture meters, and infrared cameras. Dehumidifiers extract moisture from the air, reducing the relative humidity in the affected area, while air movers increase airflow and promote evaporation. Infrared cameras can detect areas of moisture in walls, allowing restoration professionals to target these areas specifically.

It’s also important to remember that drying out wall cavities can be a time-consuming process, and it’s essential to monitor the drying progress regularly. Restoration professionals should use moisture meters to check the moisture levels in the affected area regularly. Moisture levels should be checked in both the affected area and adjacent areas to ensure that the moisture hasn’t spread beyond the affected area.

In addition to drying out wall cavities, it’s also crucial to address any underlying issues that led to the water damage in the first place. If the water damage was caused by a leak or a broken pipe, the source of the water must be fixed before restoration can begin. Failing to address the underlying issue can lead to recurring water damage and costly repairs in the future.

In conclusion, wall cavity drying is a critical component of the water restoration process, and it’s essential for restoration professionals to approach it with care and attention to detail. By using specialized drying equipment, ensuring proper ventilation, monitoring progress regularly, and addressing any underlying issues, restoration professionals can achieve successful drying outcomes and prevent further damage to the affected area.